GLASSWORKS Eyeglass CRAFTSMAN

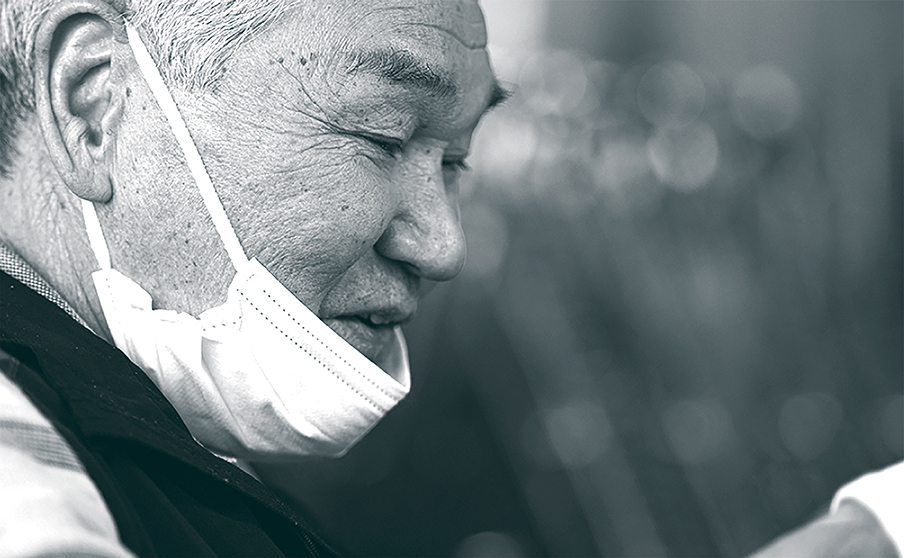

Bunji Miki

Born February 22, 1947. His name is Bunji Miki. Those who know his personality and work describe him as "courteous and symmetrical." They say one's name describes one's body, but Miki's case is unique: in the Japanese calendar even his birth date is symmetrical (22.2.22).

"In the morning when I come to work, I start with cleaning and following the radio exercise program. I've kept this habit for decades and never missed a day. Even I wonder why I'm so devoted to it. I think I'm trying to keep myself disciplined." This is the 56th year of Miki's career as an eyeglass part maker. There's almost nothing he can't do in the metal frame manufacturing process. At 75, CRAFTSMAN Miki is still at his post, fully focused on his meticulous work.

Miki's current workplace is at GLASSWORKS, KANEKO OPTICAL's dedicated metal frame manufacturing facility. In 2016, Eiko Optical, where Miki had worked for many years, was incorporated into KANEKO OPTICAL and Miki, with more experience than any other employee, was recognized as irreplaceable. His position is very unusual. All the other craftsmen and staff are younger than he is -- most a full generation or even two generations younger. Yet his position is not that of a trainer. Miki declares daily, "I want to keep making glasses as long as my body allows," and KANEKO OPTICAL has made a place for him to concentrate on that work. This position was created for Miki alone, recognizing his mastery of so many of Sabae's techniques, and his long record of reliability and accomplishment. "I've been in the Sabae eyeglass industry for many years, so I know the jobs here are declining quickly. But I still have only one thought, which is to keep making exactly what the customer wants. All I can say is, I love my work. "

Sabae 's heyday. On the front lines.

Miki comes from Okinoshima Island in Shimane Prefecture. After graduating from the local junior high school, he left his hometown as part of a group hire by Osaka Gas. After that, he left Osaka and moved to Sabae, where his sister was working at a textile company. He married, he got a job at a small local eyeglass parts company, where he was put to work making eyeglass ornamental parts and rivets. His work, such as making (gold leaf) special ornaments with 18-karat gold already required high technical skill. Eventually he began to make not only components but also entire eyeglasses, such as ready-made stainless steel reading glasses. "I went to Osaka to acquire a set of machines and tools. No one taught me. I had to teach myself the techniques and hone my skills. I devoted myself to making glasses -- the company was small, so we sold the glasses ourselves -- and we sold a lot!"

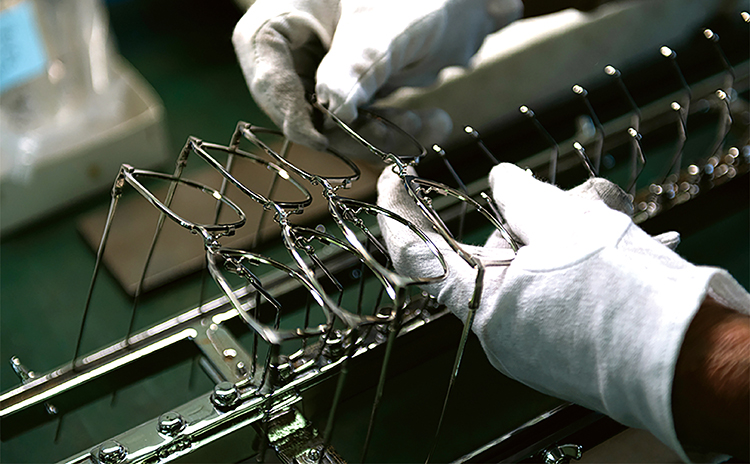

At 33, Miki moved to Eiko Optical, which developed and manufactured eyeglass frames. From then on, Miki's life was devoted to all phases of the eyeglass manufacturing process. His first project was to rebuild the manufacturing equipment and production line. Eiko Optical at the time had few machines, and the manufacturing line was weak. Production was about 2,000 pieces a month, but when the economy picked up, orders began to exceed 3,500, then 5,000, and then, in the unprecedented hot economy of the mid 80s, over 10,000 per month. Introduction of new equipment and technologies to meet these production demands was all done under Miki's leadership. The company was continuously innovating on both the hard (manufacturing equipment and lines) and soft (manufacturing technology) sides of the business, at a time when Sabae 's eyeglass industry was at its most vibrant. "We were running flat out. I had no time to rest. I'd go home every night at 11 or 12 o'clock. But, I was so absorbed in it. It was fun. Our products were selling well, so it was worth the effort." That experience is still a foundation, a strength, and a treasure for Miki in his work.

Only glasses. But glasses.

All products, not just eyeglasses, change constantly in response to the times and trends. But Miki is adamant that the idea of how eyeglasses are made is the same today as it was in the past. "Design requirements change, but when it comes to manufacturing, the basic flow is still the same. The only thing that has changed is the material. In the past, it was brass or stainless steel, and now it is alloy, aluminum, titanium, etc. Even titanium. Recently, it has changed to beta titanium. Of course, the manufacturing method and procedure change depending on the material, and the time and distribution for each material also changes in the same work process. Since I have experience dealing with all of them, now no matter what material comes I can do everything from polishing to making molds. The only thing I can't do is plating (laughs). There is no textbook, so I learn everything with my body. This is good because then no one can steal it! (Laughs) "

As a spectacle CRAFTSMAN, he always keeps in mind that "glasses are a tool to put on his face." The tools used for the most prominent parts of the human body, the face, are not unimportant to the person. In other words, I tell myself every day that I should not forget that the user attaches more importance to eyeglasses than the creator thinks. "Glasses aren't cheap and you should treat them with care. You don't treat them with your feet, right? That person treats them every day, so you have to make them one by one. Yeah, it ’s glasses, but it ’s glasses. ”

PROFILE

Bunji Miki

Born in Oki Islands, Shimane Prefecture. Born as the third son of five siblings, he got a job at Osaka Gas after graduating from junior high school. Before long my sister Sabae also own an opportunity that you are living in Sabae moved to. After getting married, he joined a company that manufactures parts such as eyeglass decorations and caulking, and started his career in eyeglass manufacturing from the manufacture of reading glasses. After that, at the age of 33, he changed his job to glory glasses and continued to support the growth of the company from the standpoint of CRAFTSMAN KANEKO OPTICAL, which took over the management of glory eyeglasses, and continues to make eyeglasses as an CRAFTSMAN at the company's metal frame manufacturing base "GLASSWORKS".

"In the morning when I come to work, I start with cleaning and following the radio exercise program. I've kept this habit for decades and never missed a day. Even I wonder why I'm so devoted to it. I think I'm trying to keep myself disciplined." This is the 56th year of Miki's career as an eyeglass part maker. There's almost nothing he can't do in the metal frame manufacturing process. At 75, CRAFTSMAN Miki is still at his post, fully focused on his meticulous work.

Miki's current workplace is at GLASSWORKS, KANEKO OPTICAL's dedicated metal frame manufacturing facility. In 2016, Eiko Optical, where Miki had worked for many years, was incorporated into KANEKO OPTICAL and Miki, with more experience than any other employee, was recognized as irreplaceable. His position is very unusual. All the other craftsmen and staff are younger than he is -- most a full generation or even two generations younger. Yet his position is not that of a trainer. Miki declares daily, "I want to keep making glasses as long as my body allows," and KANEKO OPTICAL has made a place for him to concentrate on that work. This position was created for Miki alone, recognizing his mastery of so many of Sabae's techniques, and his long record of reliability and accomplishment. "I've been in the Sabae eyeglass industry for many years, so I know the jobs here are declining quickly. But I still have only one thought, which is to keep making exactly what the customer wants. All I can say is, I love my work. "