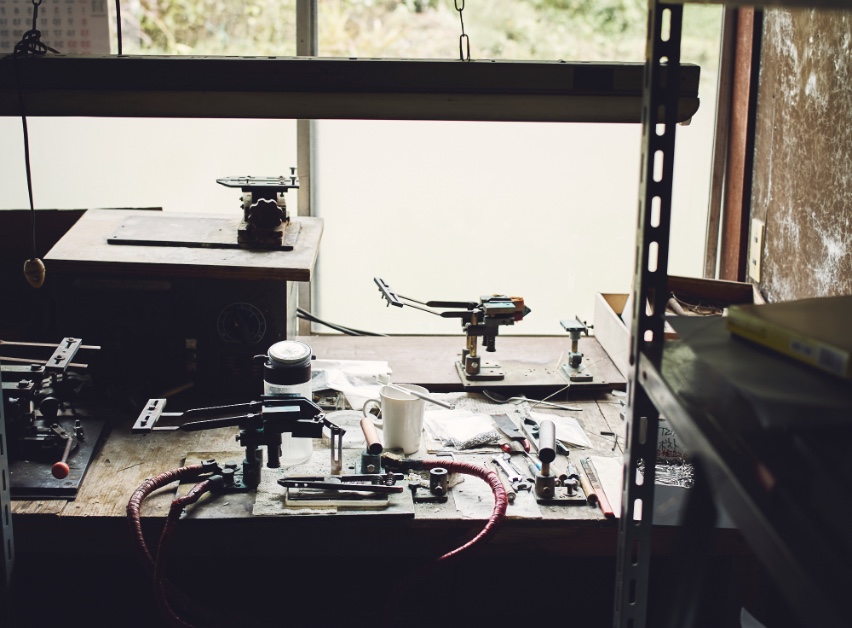

Disciplined handwork.

The true essence of polishing and luster.

From exploration and research

comes refined detail.

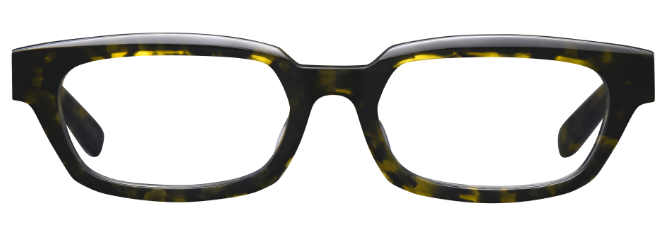

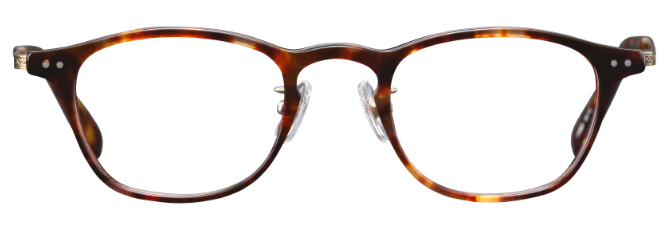

Mr. Ido's Ichiyama frames are made with close attention to detail, such as a nose pad height fitted to Japanese faces, traditional asymmetrical hinges,* and outwardly turned temple ends for ease of donning and removal. Ido manipulates massive stationary tools as an extension of his own hands, applying long-cultivated techniques to create fine detail, stripped of all excess. *In asymmetrical hinges, the fastening screws on the left and right face in opposite directions, one up, one down, to assure minimal and equal loosening on both sides over time.

Emotional resonance from human hands.

A craftsman's lifelong study

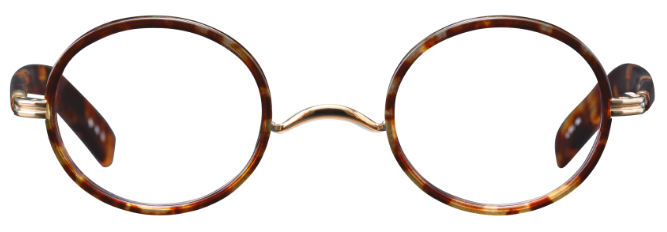

Exquisite finish rooted in long history.

Standing at the pinnacle.

Both Technique and Material