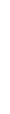

"KC Series" is an abbreviation for KANEKO CELLULOID. Different from the acetate materials in use by virtually all other manufacturers, our celluloid material requires very high technical skill to handle, and a large number of manufacturing steps. Its great appeal, unavailable with other materials, comes from its distinctive feel and texture on the skin, and its deep color and luster, which changes over time.

The process of "laying down" and "polishing" is performed to bring out its true value. Celluloid is reborn as a hard and durable material by drying it for a long time and letting it lie down. After that, in buffing, which is an important process that occupies two-thirds of the total, various types of buffs are used properly for each part and process, and by repeating hand polishing, a deep luster is created.

The KC series includes models incorporating traditional Sabae methods, such as "no-core" manufacturing, in which no reinforcing metal core is embedded in the temples, or the use of rugged 5-tenon hinges. Other models, while still using celluloid, employ standard manufacturing methods (with cores). The KC series offers a wide lineup, using optimal manufacturing methods without compromising design or fashion impact.

Everything we do takes time - from the demanding techniques for polishing celluloid to the fine details of design. Eyewear constantly contacts the wearer's skin. We take that to heart, so we don't mind spending the time required to be thorough. The people of KANEKO OPTICAL don't just make glasses to sell - we sincerely consider how our eyewear adds to the lives of our customers after leaving our hands.

The "KV (KANEKO OPTICAL VINTAGE) SERIES" proposes a new vintage style that combines classical details found in Boston and Wellington frames with a modern esthetic. Transcending the age, this eyewear will live on with unfading appeal. That's KANEKO OPTICAL VINTAGE.